Bin, Tank, and Hopper Scales

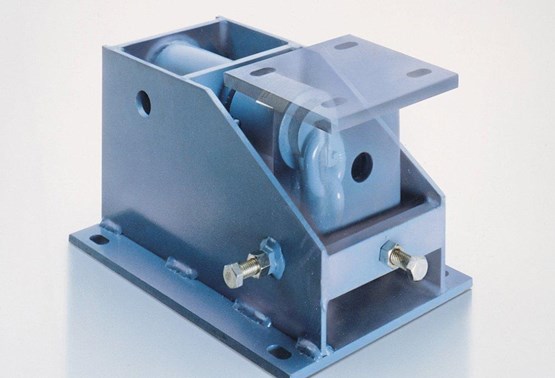

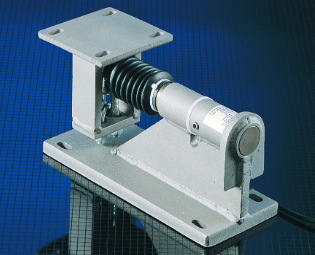

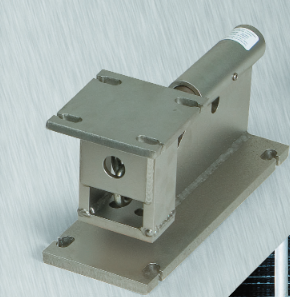

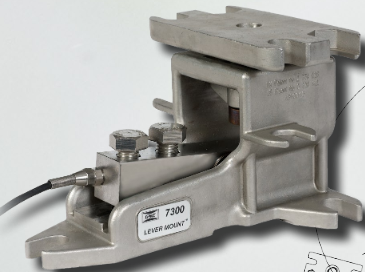

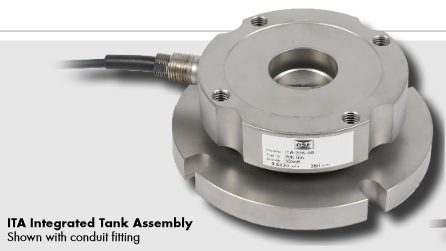

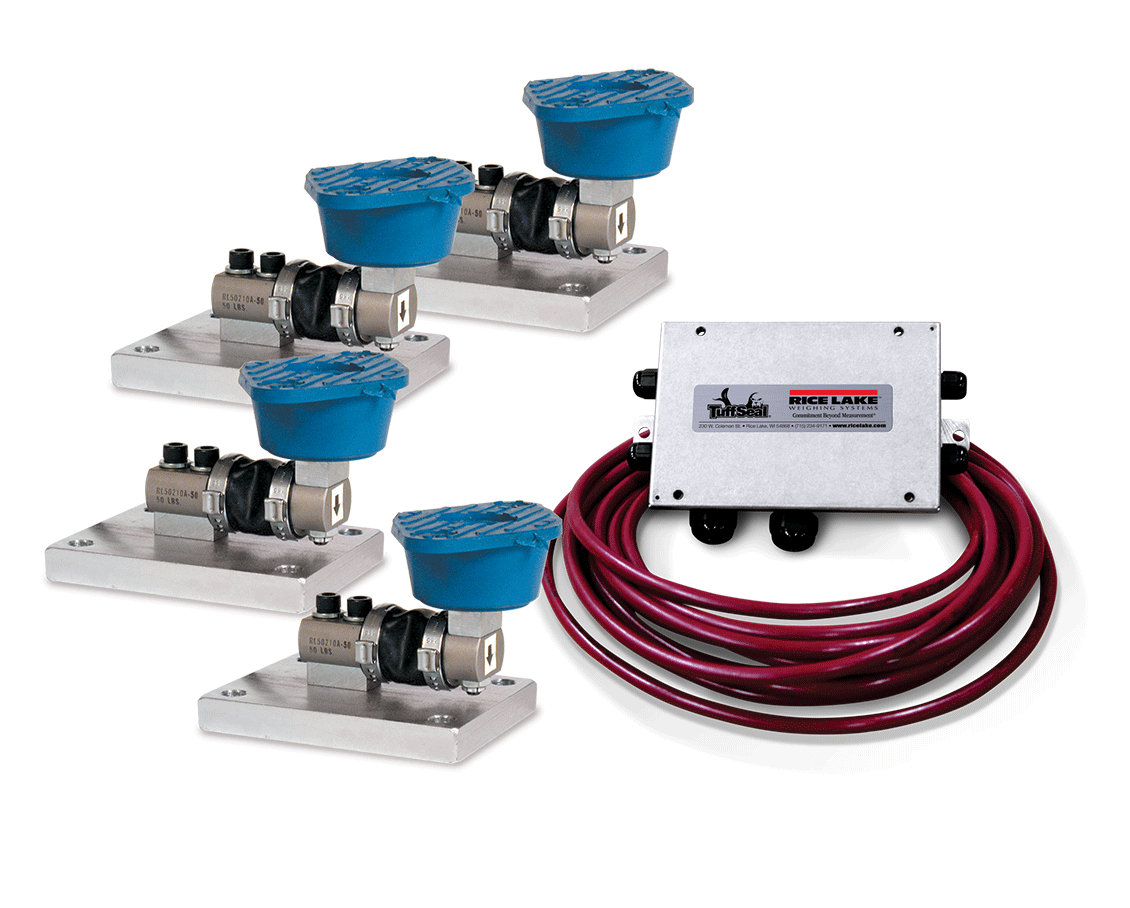

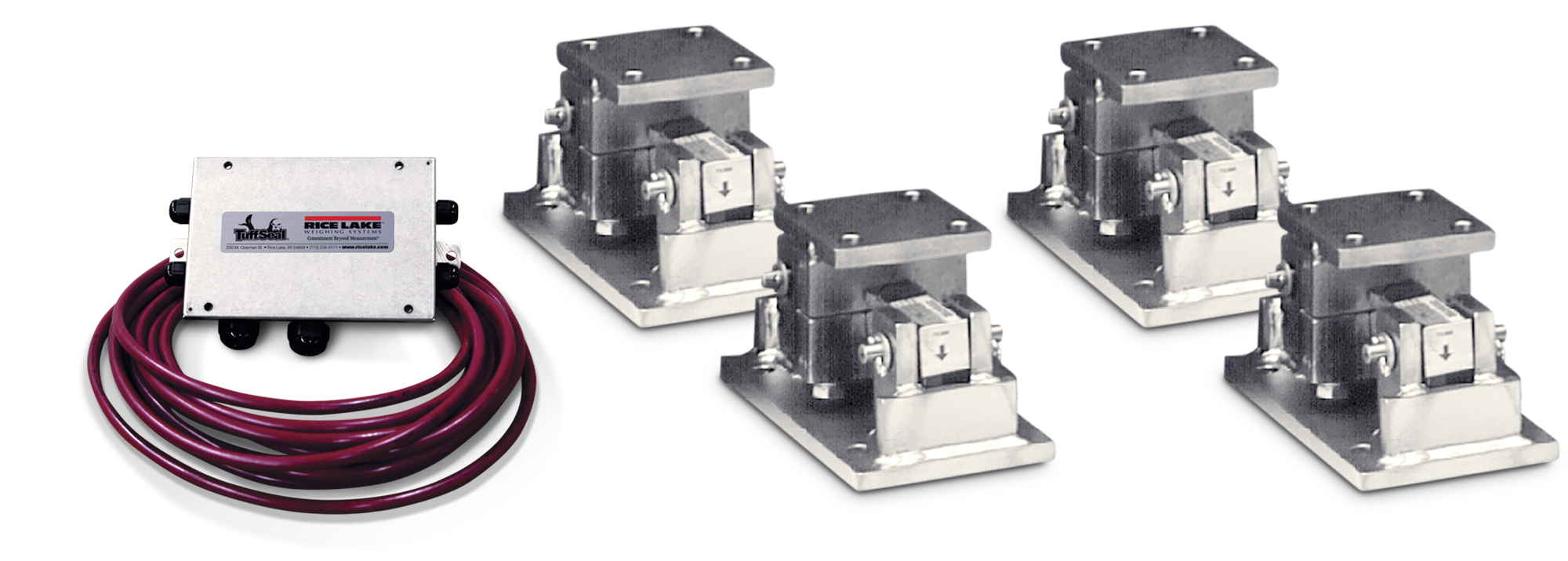

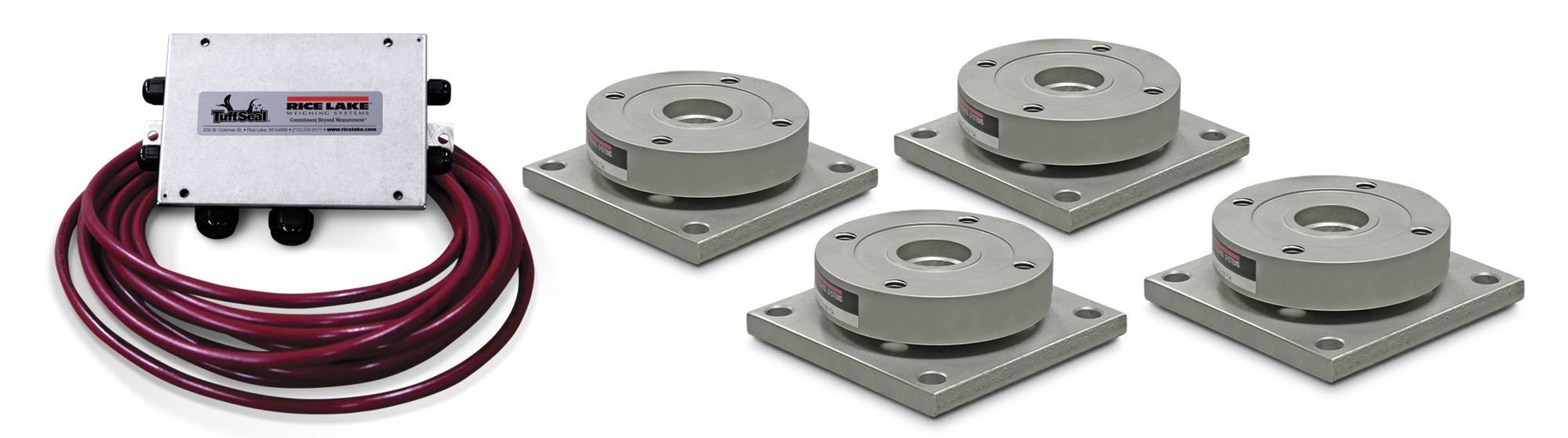

Bin, Tank, and Hopper Scales are generally custom designed to fit a particular process. They are used heavily in food and chemical processing. Some have simple Bin Level Indicators to avoid running out of material or to avoid getting air in the lines. Others have complex Recipe or Menu Based Batching Systems that involve gates, valves, conveyors, mixers, heaters, etc. Including weighing in a process adds a level of complication beyond material handling. The vessel must be free to move vertically without restriction. This requires that ANY connection to the vessel be flexible both horizontally and vertically. Many manufacturers produce load cells or Weigh Bars with mounts suitable to support vessels of all types. See our Sections on Load Cells and on Weigh Bars. They are available in alloy steel and in stainless steel for wet or corrosive environments. They are available as FM approved for use in Hazardous Areas. We have all the latest instrumentation and communication interfaces – both hardwired and wireless. See our Section on Weight Indicators. The weight sensors and instrumentation we sell and service are from quality conscious, ISO accredited, manufacturers.

The following is representative of what we offer. It is not exclusive. Please contact us with your requirements.

Click on the Manufacturer name below for their Bin, Tank, and Hopper Scales

|

|

|

|

Bin, Tank, and Hopper Scale Manufacturers

|

|

|

Application notes for the proper installation of Vessel Weighing Systems (from Vishay Precision Group) |

|

|

App Note 02 - Load Cell Accuracy in Relation to conditions of use |

|

|

Application notes for the proper installation of Vessel Weighing Systems (from Rice Lake Weighing Systems) |

|

|

Weigh Modules and Vessel Weighing Systems Installation and System Guidelines |

|