Balances and scales are very precise instruments and

like all instruments, they perform within stated

parameters.

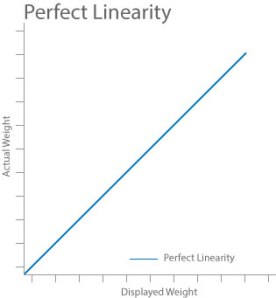

Basically, linearity is a deviation (or no deviation)

from a straight line. If we draw a graph with weight at

one side and displayed value on the other, a purely

linear balance would show a straight 45° line from the

zero point, right up to full capacity. Each time the

load increases, the displayed value increases at the

exact same rate, thus giving the straight line. See Fig.

1. (Please note that the errors in the graphs used below

are exaggerated to provide clarity).

Figure 1

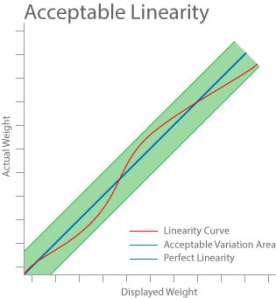

In Fig. 2. We see an example of the allowed linearity

of an analytical balance of 200 g with an allowable

linearity of ± 0.0002 g. This example shows the error

allowed around the “perfect” linearity. The green shaded

area represents the permissible error allowed.

Figure 2

In Fig. 3. We show the typical linearity of a 200 g

balance, with a slight positive error (0.0001 g) below

100 g and a slight negative error over 100 g of 0.0002

g. This balance is just within specification.

Figure 3

In Fig. 4. We see a balance that is just outside the

tolerance allowed, as the curve of the displayed value

exceeds the ±0.0002 g permissible error.

Figure 4

Manufacturers and scale dealers have the ability to

correct errors in linearization by adjusting the balance

with test weights at regular intervals of the capacity.

Linearization is not calibration that can be performed

with a single weight. Linearization should not be

attempted without specialist knowledge and the correct

test weights.